Project: Baby changing table for regional trains.

Client: Stadler AG, Berlin

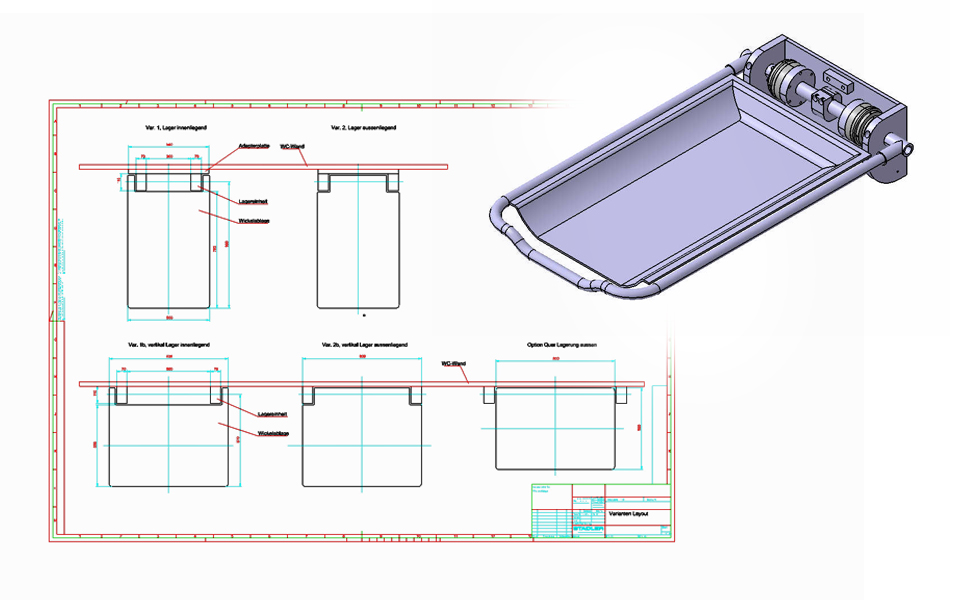

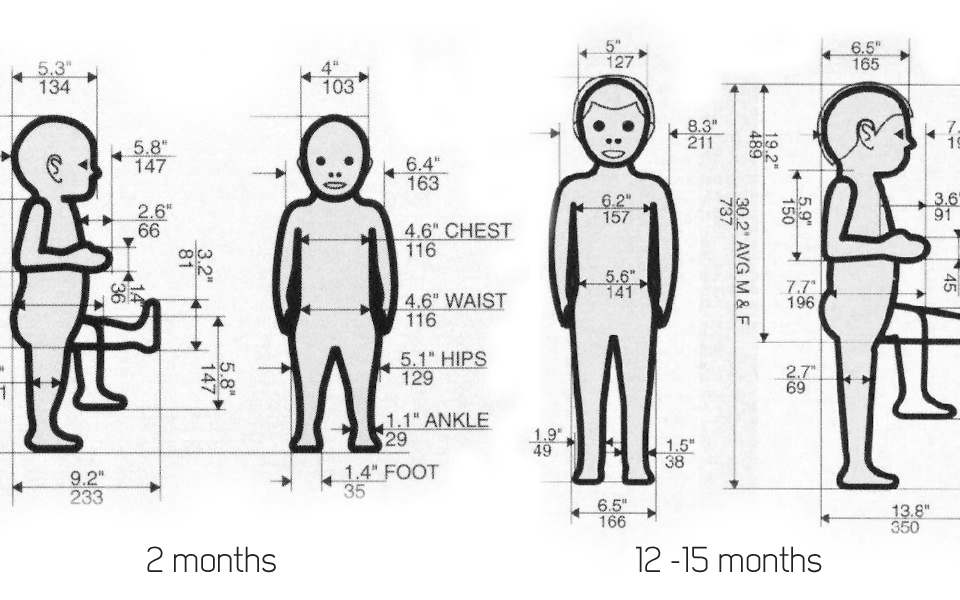

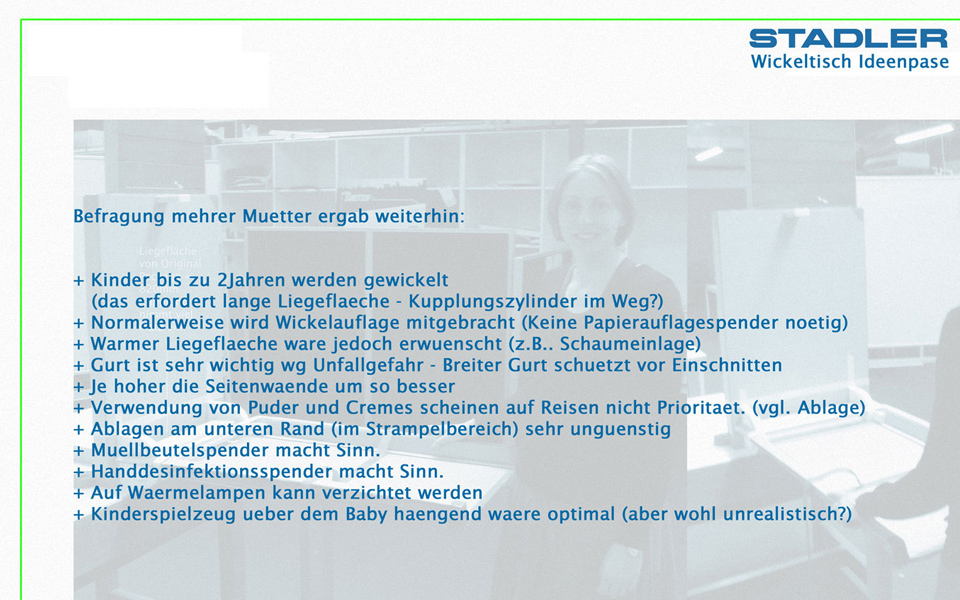

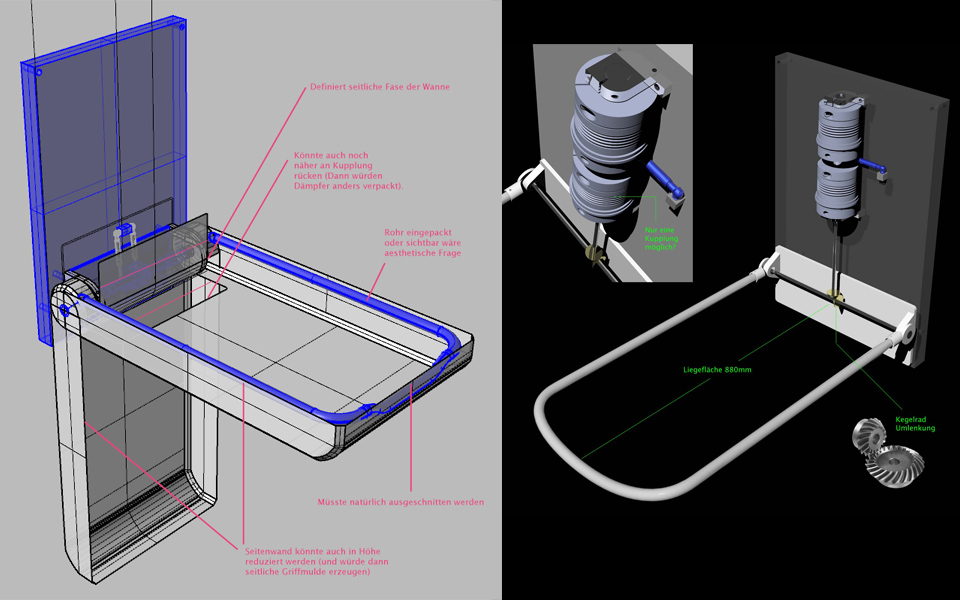

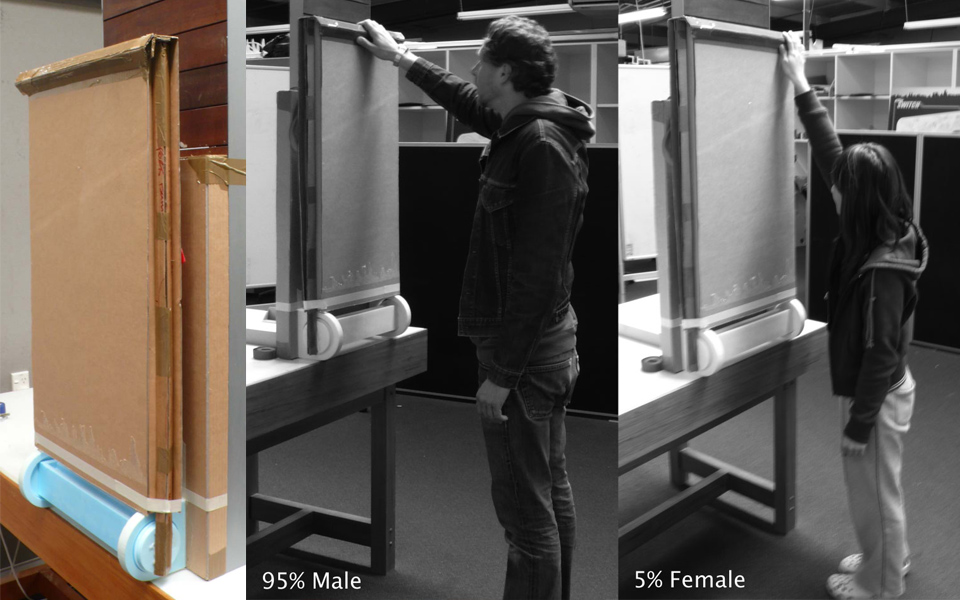

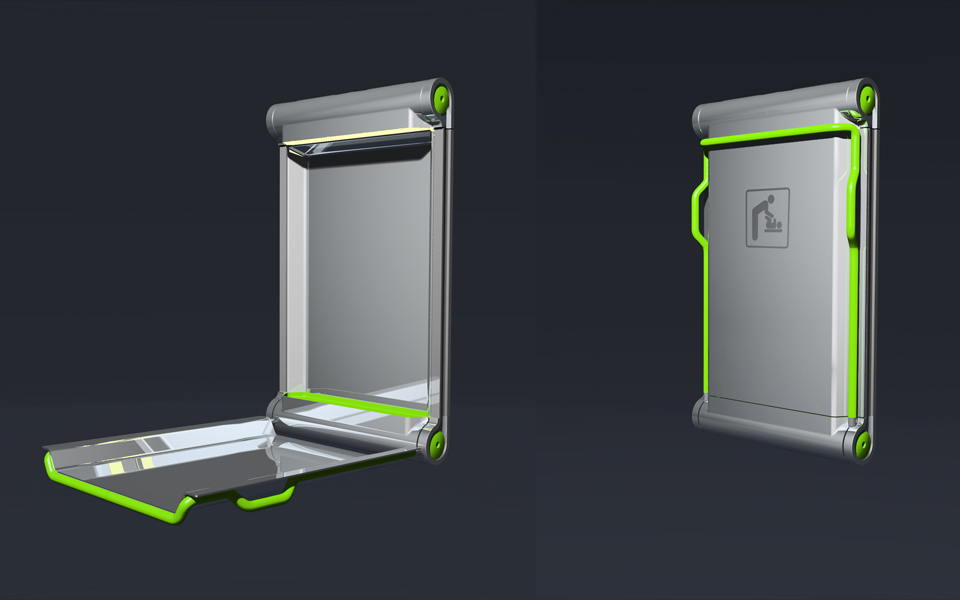

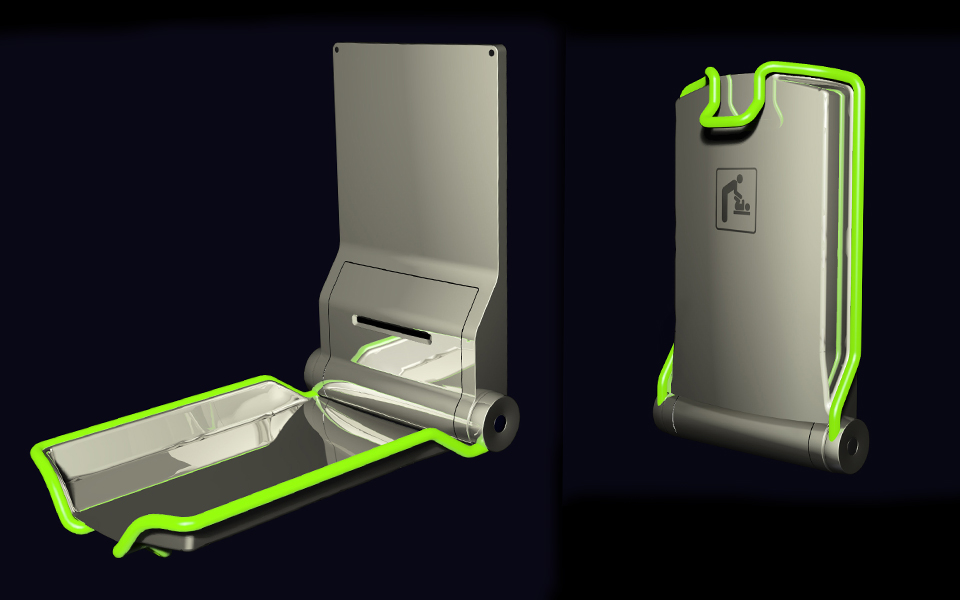

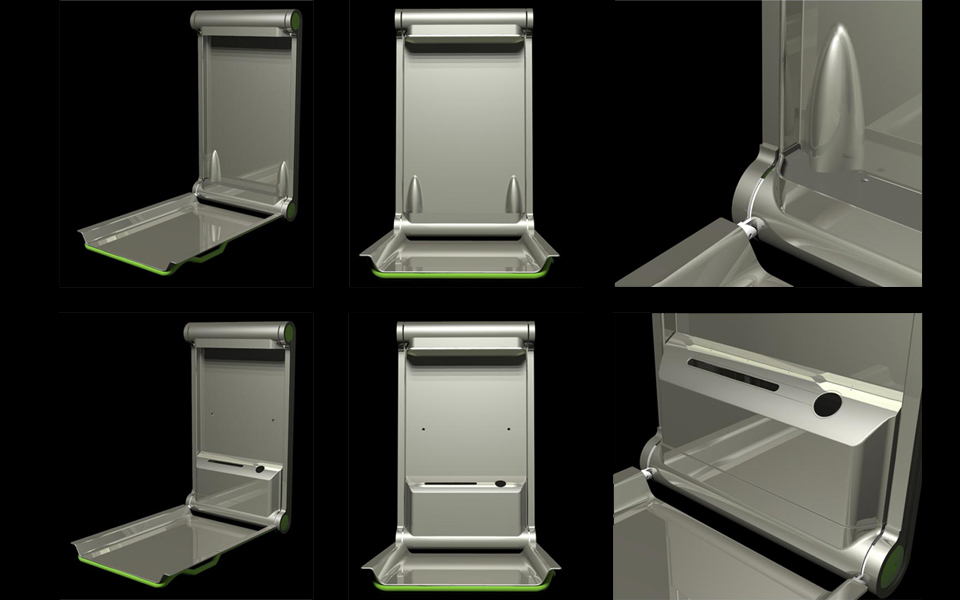

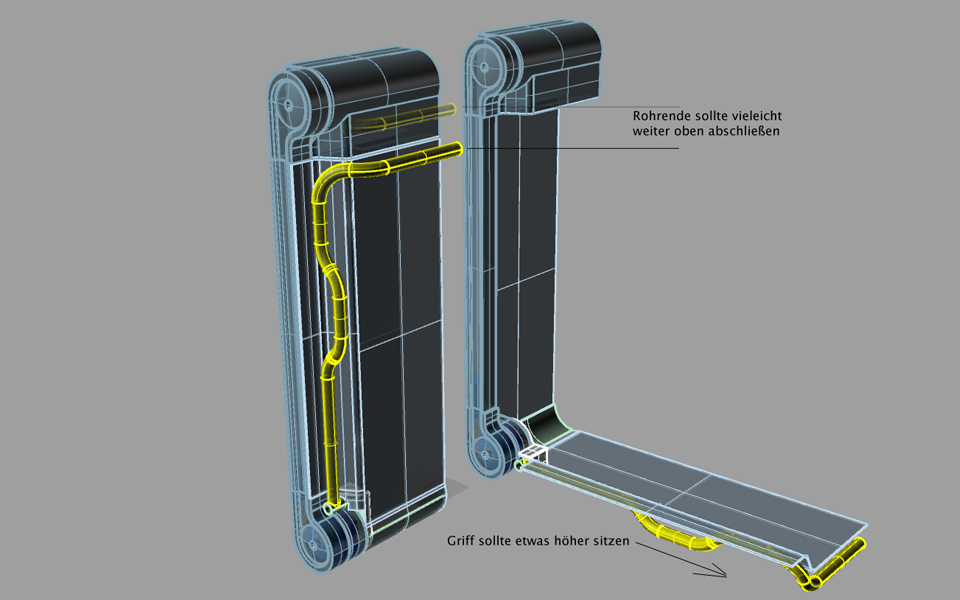

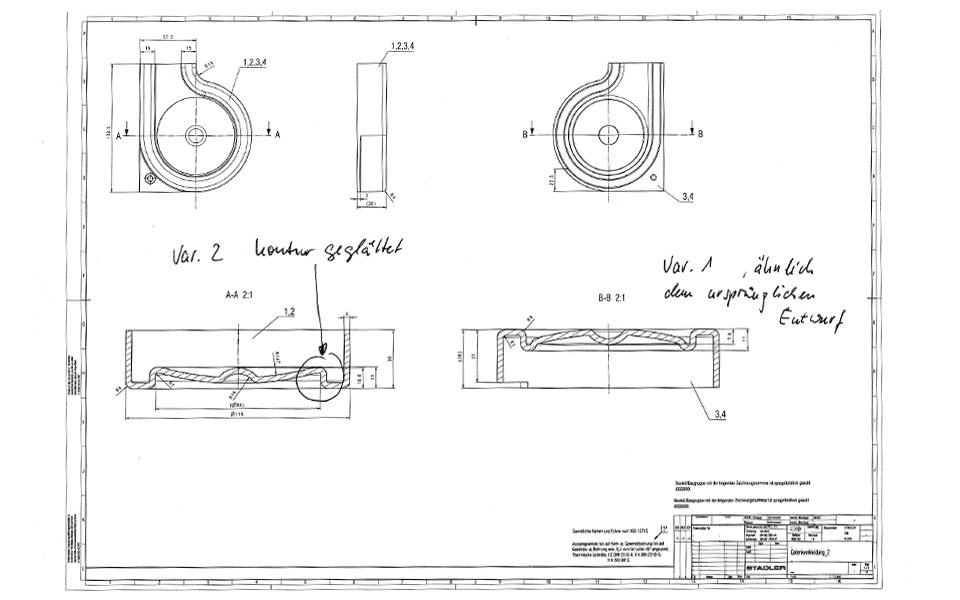

This project was done in collaboration with an rail engineering consultancy for the train manufacturers Stadler Pankow GmbH. The task was to design an in-house component for tight regional train bathrooms using an vertical (portrait) layout. One of the main issues addressed was overloading of the changing tables by passengers trying to sit on them. With current products this usually led to an safety collapse which required a technician to come on board to repair the unit. The engineers had suggested a overload clutch system which could be re-set by the train conductor rather than an technical - saving maintenance and repair cost.

OND was approached early in the project to work with the engineers on the design (human factors/ appearance/ usability) of the unit. The overload clutch layout was given as well as the space and positioning in the train bathroom. The rail industry also has to obey an array of legal standards and restrictions which had to be considered. However there was room to work on the human centred side of the component and creating a Stadler-unique solution (instead of using standard supplier stock).

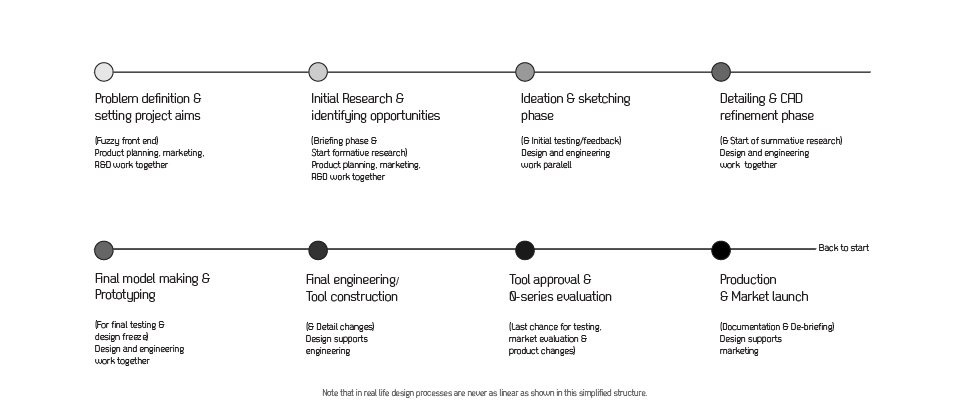

After an initial briefing session and review of the technical data (package) provided, OND conducted formative research to inform the following ideation phase. This was the development process in detail...

How to get started

Note down some keywords around your project.

Use Mind map template to get started (download here). Additionally compile some visual material explaining

your project or inspirations.

Summarize essential information about the project you envision. This can be simply re-styling a product or technical concept, idea visualization, new product development, identify opportunities through market and trend reviews or new technology or material use. See project brief as a guide.

Get in contact with us to arrange an initial free consultation and quote. Feel free to propose what the work would be worth to you - we will look into reasonable proposals if the challenge is interesting to us.

Arrange a kick-off workshop with all parties/people involved in the project to collect all existing information, ideas, want and needs. Invite at least a representative of decision makers and strategic leaders, marketing, product planning, engineering (R&D), production/manufacturing and design team.

This will enable a flying start with clear communication and already a pile of feasible ideas to work on and test. We are trained moderators and enable a efficient and result-driven use of the groups time together.

Mindmap Project Brief K-WorkshoP